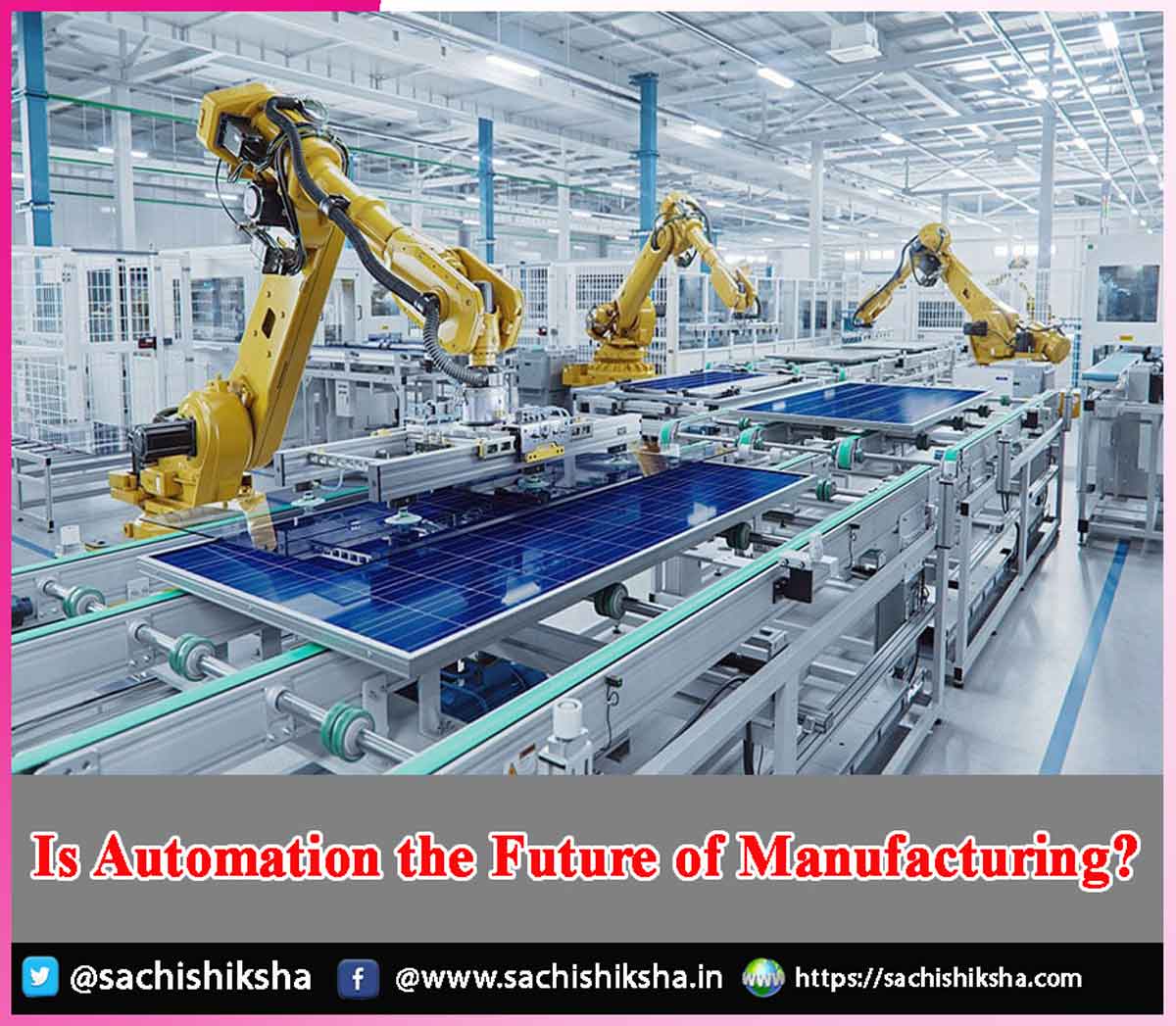

Is Automation the Future of Manufacturing?

Introduction: The manufacturing industry has always been at the forefront of innovation, adapting to technological advancements to improve efficiency, reduce costs, and enhance product quality. From the advent of steam engines during the Industrial Revolution to the rise of assembly lines, every significant leap in manufacturing has been driven by new technologies. Today, automation is emerging as the next major evolution, redefining how goods are produced and distributed. But is automation truly the future of manufacturing? To answer this, it’s essential to explore its potential benefits, challenges, and long-term implications.

Table of Contents

Understanding Automation in Manufacturing

The Driving Forces Behind Automation

Several factors are propelling automation forward in the manufacturing sector:

- Rising Labor Costs:

As wages increase globally, especially in developing economies, manufacturers are under pressure to reduce labour costs. Automation offers a solution by replacing repetitive, low-skill tasks with machines that can operate continuously without breaks. - Demand for Precision and Consistency:

Consumers today expect high-quality products with minimal defects. Automated systems excel in tasks requiring extreme precision, significantly reducing human error and improving product consistency. - Technological Advancements:

Innovations in robotics, AI, machine learning, and the Internet of Things (IoT) have made automation more accessible and cost-effective. These technologies enable machines to perform complex tasks, learn from data, and adapt to new challenges. - Global Supply Chain Disruptions:

Events like the COVID-19 pandemic exposed vulnerabilities in global supply chains, prompting manufacturers to adopt automation as a means of increasing resilience and reducing dependence on manual labour. - Sustainability Goals:

Automation can contribute to sustainability by optimizing resource use, minimizing waste, and enabling energy-efficient production methods.

Advantages of Automation in Manufacturing

Automation offers several significant advantages that make it an attractive proposition for manufacturers:

- Increased Productivity:

Automated systems can operate 24×7, significantly boosting output and meeting growing consumer demands without increasing labour hours. - Cost Efficiency:

Although the initial investment in automation technology can be high, the long-term cost savings from reduced labour expenses, minimized errors, and increased efficiency often outweigh the upfront costs. - Enhanced Product Quality:

Machines programmed to follow precise instructions ensure uniformity and quality across all production batches, reducing the likelihood of defective products. - Workplace Safety:

Automation reduces the need for human workers to perform hazardous tasks, lowering the risk of workplace injuries and improving overall safety. - Flexibility and Scalability:

Modern automated systems are adaptable, allowing manufacturers to switch between products or scale up production with minimal downtime.

Challenges and Concerns

While automation holds immense promise, it is not without its challenges and concerns:

- High Initial Investment:

Setting up an automated manufacturing system requires substantial capital, which may be prohibitive for small and medium-sized enterprises (SMEs). - Job Displacement:

One of the most significant concerns is the potential loss of jobs due to automation. Workers performing repetitive or low-skill tasks are particularly vulnerable, raising ethical and social issues. - Complex Maintenance and Repairs:

Advanced machinery requires specialized knowledge for maintenance and troubleshooting, necessitating additional training or hiring of skilled personnel. - Cybersecurity Risks:

As factories become more connected, they are increasingly vulnerable to cyberattacks that could disrupt production or compromise sensitive data. - Resistance to Change:

Organizational inertia and resistance from workers and management can slow the adoption of automation technologies.

The Role of Emerging Technologies

The success of automation in manufacturing is being driven by several emerging technologies:

- Artificial Intelligence (AI) and Machine Learning:

AI enables machines to analyse vast amounts of data, optimize processes, and even predict maintenance needs. Machine learning algorithms allow systems to adapt and improve over time. - Collaborative Robots (Cobots)

Unlike traditional industrial robots, cobots are designed to work alongside human workers, enhancing productivity and reducing the fear of job displacement. - Additive Manufacturing (3D Printing):

Automation extends to additive manufacturing, where machines can produce complex designs with minimal material waste, revolutionizing industries like aerospace and healthcare. - IoT and Smart Factories:

IoT technology connects machines, sensors, and systems, creating smart factories capable of real-time data sharing and decision-making. - Autonomous Vehicles:

Autonomous vehicles are streamlining logistics within factories and across supply chains, reducing transportation costs and improving delivery times.

Case Studies in Automation

Several industries have already embraced automation with impressive results:

- Automotive Industry:

The automotive sector has long been a pioneer in automation, with robotic arms handling tasks like welding, painting, and assembly. Companies like Tesla and Toyota continue to push the boundaries of automated manufacturing. - Electronics Manufacturing:

Automation is crucial in electronics production, where precision and miniaturization are critical. Firms like Foxconn use advanced robotics to assemble smartphones, laptops, and other devices. - Food and Beverage Industry:

Automated systems are widely used for packaging, labelling, and quality control in food manufacturing, ensuring hygiene and consistency. - Healthcare and Pharmaceuticals:

The pharmaceutical industry relies on automation for tasks such as drug formulation, filling, and packaging, improving efficiency and ensuring regulatory compliance.

Balancing Automation with Human Labor

Rather than fully replacing human labour, the future of manufacturing lies in a hybrid model where humans and machines complement each other. Automation can handle repetitive, dangerous, or precision tasks, while humans focus on creative, strategic, and interpersonal roles. This approach not only maximizes efficiency but also preserves jobs and enhances worker satisfaction.

Government Policies and Ethical Considerations

Governments and policymakers play a crucial role in shaping the future of automation in manufacturing. They must address concerns like job displacement through initiatives such as:

- Skill Development Programs: Offering training in robotics, AI, and other relevant technologies to upskill workers.

- Support for SMEs: Providing subsidies or low-interest loans to help smaller manufacturers adopt automation.

- Ethical Guidelines: Establishing frameworks to ensure that automation benefits society as a whole.

Conclusion: Automation is undoubtedly the future of manufacturing, offering unparalleled opportunities to enhance productivity, reduce costs, and improve quality. However, its widespread adoption must be carefully managed to address the associated challenges, including job displacement and ethical concerns.

By fostering collaboration between industry, governments, and workers, the manufacturing sector can leverage automation to create a more efficient, sustainable, and inclusive future. The key lies in viewing automation not as a threat to human labour but as a tool to unlock new possibilities, empowering workers and businesses alike to thrive in an increasingly competitive global market.